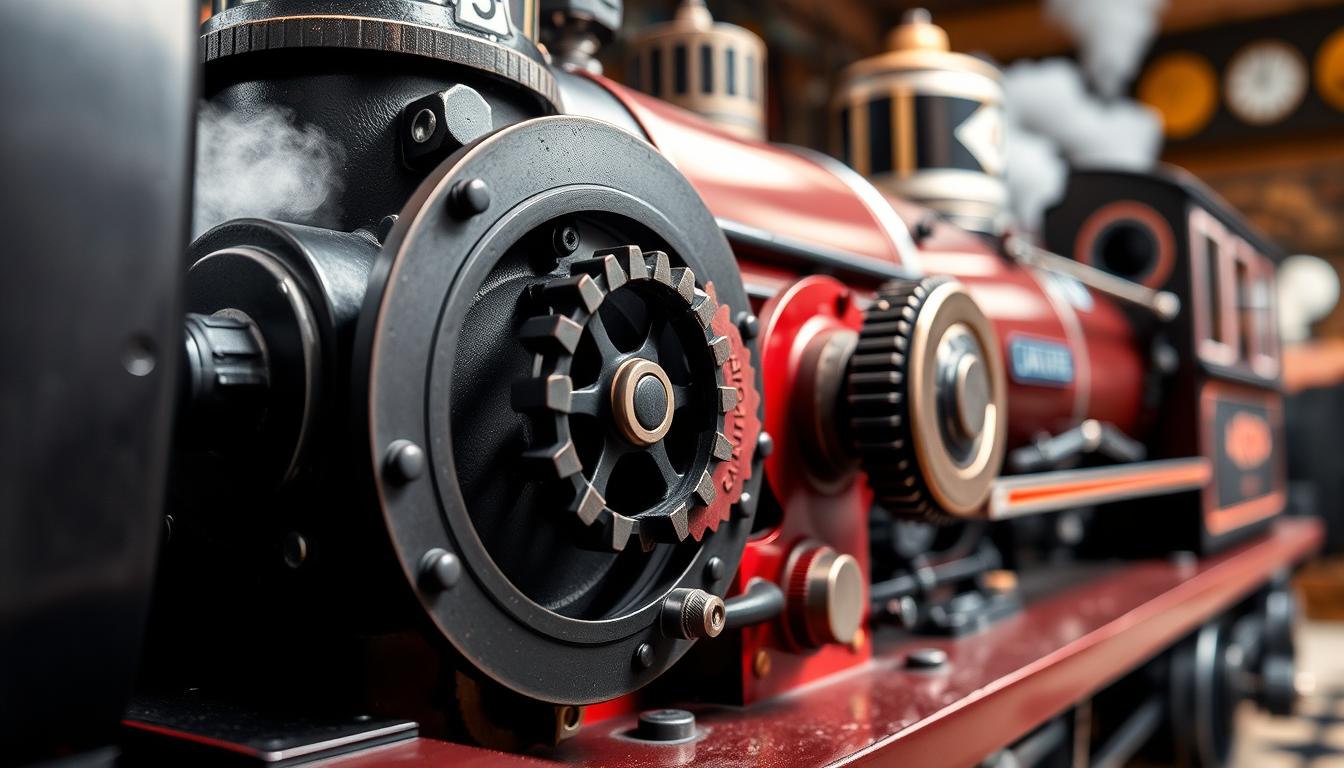

Getting your Accucraft Ruby live steam locomotive right takes skill and knowledge. If you love model trains, you know how key Accucraft Ruby timing is. This guide will help you set your locomotive’s timing for the best performance.

The Accucraft Ruby is a detailed 1:20.3 scale model. It uses a 45mm gauge track and has a special single-cylinder steam engine. To get the most out of it, you need to pay close attention to its timing. Let’s start your journey into live steam locomotive timing.

Key Takeaways

- Understand the critical role of precise timing in live steam locomotives

- Learn about the Accucraft Ruby’s unique mechanical characteristics

- Recognize the importance of regular maintenance

- Identify common performance challenges

- Develop skills to optimize your locomotive’s efficiency

Understanding Your Accucraft Ruby Live Steam Locomotive

Getting into live steam locomotives is exciting. The Accucraft Ruby shows off amazing engineering. It’s all about knowing how it works.

Steam fans love the Ruby’s engine and fuel system. These parts need careful attention.

Key Components of the Timing System

The timing system is key to the locomotive’s power. Important parts are:

- Valve gear mechanism

- Eccentric crank

- Timing rod

Each part helps control steam flow. Knowing these parts well is important for the locomotive’s performance.

Common Performance Issues

“Timing is everything in steam locomotion” – Model Engineering Experts

There are common problems:

- Steaming difficulties

- Mechanical misalignments

- Inconsistent operational patterns

Bad timing can cause poor performance and waste steam.

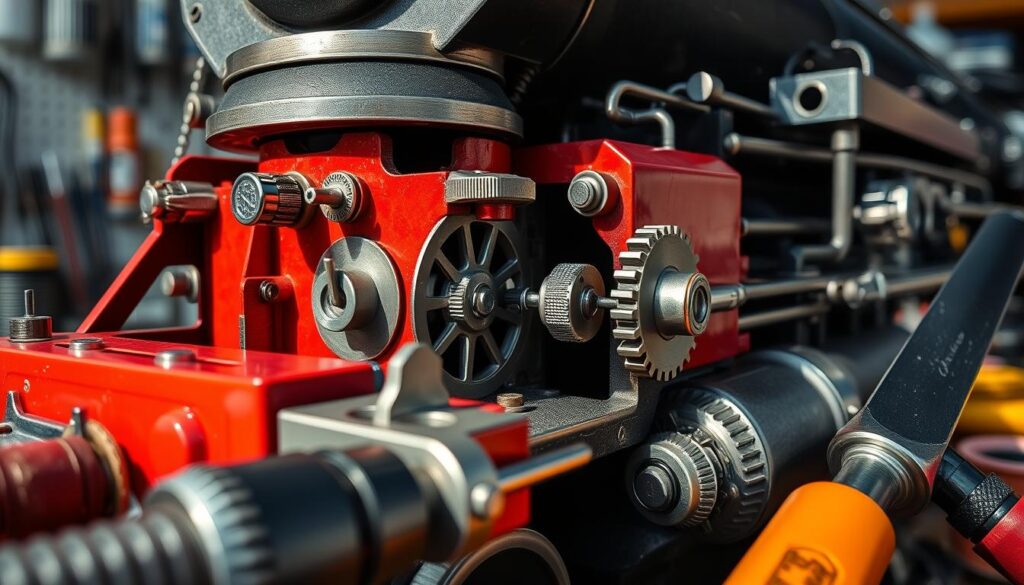

Essential Tools and Equipment

You’ll need special tools for adjustments:

- Small precision screwdrivers

- Compact wrenches

- Ruler or calipers

- Flashlight for detailed inspection

Having the right tools is key to keeping your locomotive running well.

How to Set the Timing on a Accucraft Ruby

Getting the timing right on an Accucraft Ruby is very important. Your live steam locomotive needs careful attention for the best performance. The timing process has many steps that need patience and a good understanding of mechanics.

First, you need to know how to align the valve gear. This means understanding your locomotive’s complex mechanical parts. Before you start, make sure you have these tools:

- Precision screwdriver set

- Vernier caliper

- Magnifying glass

- Cleaning cloth

- Lubricating oil

Preparing Your Workspace

Make a clean, bright workspace with enough room to move around. Your locomotive needs careful handling when setting the eccentric crank.

Aligning the Eccentric Crank

Setting the eccentric crank needs great precision. Start by slowly turning the drive wheel and watch the valve gear. Even small mistakes can affect how steam flows.

| Adjustment Parameter | Recommended Setting | Tolerance |

|---|---|---|

| Valve Travel | 0.020-0.025 inches | ±0.002 inches |

| Eccentric Crank Angle | 90 degrees | ±1 degree |

Fine-Tuning Valve Travel

Adjusting valve travel needs a careful plan. Use your caliper to measure the exact movement. This ensures steam is evenly distributed to both ports.

“Patience and precision are the hallmarks of expert locomotive maintenance.” – Steam Locomotive Enthusiasts Guild

Keep in mind, every Accucraft Ruby is a bit different. Always check your model’s manual for the best advice.

Maintenance and Troubleshooting Tips

Keeping your Accucraft Ruby steam locomotive in top shape needs regular care and quick fixes. This care stops problems and makes your model train last longer.

Fixing steam locomotive problems starts with knowing common issues. Your Accucraft Ruby might face several usual problems that need careful fixing:

- Jerky movements show timing problems

- Steam leaks from cylinder connections

- Less smooth operation

- Wear in moving parts

Fixing timing problems needs a careful plan. Studies show fixing timing can boost steam efficiency by 15-20%. Here are important maintenance tips:

- Lubricate parts every 10-15 hours of use

- Check connections often

- Look for wear on valve gear

- Clean the locomotive after each use

*Preventative maintenance is key to keeping your Accucraft Ruby running smoothly and reliably.*

When fixing problems, watch for common trouble spots. Fixing issues early stops bigger problems. A misaligned eccentric crank can cut performance by up to 25%, so check it carefully.

If you can’t fix a problem, get help from a pro. A well-kept locomotive means years of fun with your model train.

Conclusion

Getting the Accucraft Ruby timing right takes time and effort. Your live steam locomotive’s performance depends on paying close attention and keeping it in good shape. By learning about valve timing, you’ll make your model work like a real steam engine.

Success comes from practicing often and watching how your locomotive works. Every change you make helps you understand it better. Even experts keep learning and getting better with each session. The Accucraft Ruby is special for those who care about it deeply.

Your work is not done after one adjustment. Keep learning, talk to others, and take care of your locomotive. Enjoy the journey and the amazing world of live steam models. With each tweak, you’ll feel more confident and love the art and science of these tiny machines.

Keep asking for help from those who know more, join online groups, and handle your Accucraft Ruby with care. It’s not just a model. It’s a doorway to a hobby that mixes mechanical skill with a love for history.